How to choose the suitable dry ice making machine for yourself? The selection factors of dry ice manufacturing machine are revealed!

Dry ice has become an indispensable material in industrial production, scientific research experiments, and daily life due to its unique physical properties, such as extremely low temperature and low residue retention. Choosing the appropriate dry ice manufacturing machine model is not only related to production efficiency and cost, but also directly affects the quality and safety of the product. Below, we will explore how to scientifically and reasonably choose the model of dry ice factory machine from multiple dimensions.

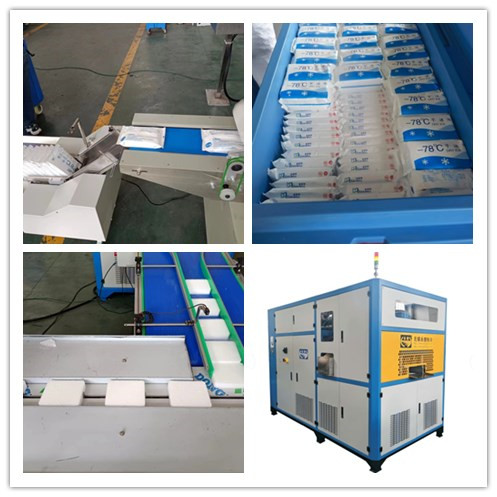

Firstly, clarifying one's own demand for dry ice is the basis for selecting a machine model. If the daily usage is small, such as for home or small-scale laboratory use, small capacity dry ice maker such as YGBK-50-1 can be prioritized. For scenarios such as large factories, cold chain transportation, or cleaning services that require a large amount of dry ice, models with higher production capacity and stronger stability should be selected to ensure sufficient supply.

Different application scenarios have different requirements for the size and shape of dry ice pellet. For example, the dry ice cleaning industry typically requires smaller pellet to achieve better cleaning results; In the field of food preservation, it may be more inclined to use block dry ice to extend the preservation time. Therefore, when choosing a dry ice maker, it is necessary to determine the required particle size and shape based on actual needs to ensure that the product meets the usage standards.

The performance and stability of equipment are directly related to production efficiency and product quality. Choosing a well-known brand with guaranteed quality dry ice pelletizer machine can greatly reduce the risk of production interruption caused by equipment failure. At the same time, understanding key indicators such as conversion rate and energy consumption ratio of equipment is also an important aspect of evaluating equipment performance.

The maintenance and after-sales service of the equipment cannot be ignored. Choosing a brand that provides comprehensive after-sales service and can quickly respond to repair needs can ensure good maintenance and upkeep of the equipment during long-term use, extend its service life, and reduce overall costs.

Although price is an important consideration when choosing equipment, it is not the only criterion. High price does not necessarily mean high quality, and low price may also hide hidden risks in quality and service. Therefore, when choosing a dry ice pellet machine, multiple factors such as equipment performance, stability, and after-sales service should be comprehensively considered to select the product with the highest cost-effectiveness.

In China, there is an integrated supplier specializing in the production, research and development, and sales of dry ice, dry ice machines, and dry ice cleaning machines -Magicball Technology. The company is committed to providing customers with high-quality and cost-effective dry ice manufacturing solutions, relying on advanced modern equipment, a high-quality management team, and a strong R&D team with technical strength. Whether it is a small laboratory or a large-scale industrial production, Wuai Air Conditioning can provide customized dry ice making machine models and services according to your actual needs. Choose Magicball to make your dry ice production more efficient, convenient, and safe.